Enhancing the Efficiency: A Comprehensive Guide to Automation via Inventory Management Technology

In today’s click-to-shop era, getting the right product to a customer precisely when they want it is akin to hitting a moving target. Amidst fierce competition and shifting consumer tastes, exceptional inventory management isn’t a luxury — it’s a must.

The age of manual logs, paper records, and gut decisions in inventory? That’s history. The digital age demands an upgrade.

Enter the new dawn of inventory management: Automation. This revolutionary shift, driven by cutting-edge inventory management technology, is ushering in a “golden age” of streamlined and efficient inventory processes.

Dive with us into this blog as we explore the nuances of automated inventory management —its technology, benefits, challenges, and the roadmap to its adoption.

What is Inventory Management Automation (IMA)?

Inventory Management Automation (IMA) refers to the process of using technology to effortlessly manage inventory aspects like tracking products, orders, and sales, eliminating manual tasks. Its aim? Boost efficiency, minimize errors, ensure product readiness, and conserve resources.

With IMA, businesses gain instant inventory visibility, streamlining stock and sales across diverse locations. It slashes mistakes, speeds up operations, provides immediate data, sharpens inventory insights, and aids swift, autonomous decisions.

Furthermore, a salient feature of IMA is its capacity to integrate seamlessly with other e-commerce solutions, such as ERP, MES, and sales platforms. This interoperability guarantees real-time inventory precision, operational efficiency, and sustained profitability, aligning businesses with multichannel sales dynamics.

The Key Factors Driving The Ima Adoption:

Demand for Real-time Data:

Modern e-commerce businesses rely on real-time data for informed decision-making. Automated systems deliver instantaneous stock updates, sales metrics, and trend analyses, allowing businesses to respond swiftly to market changes.

Streamlined Workflows and Error Reduction:

Manual processes are prone to human error, including data entry mistakes and stock count oversights. Automating these tasks minimizes errors, ensuring precise and reliable inventory data. Automation simplifies inventory processes, resulting in quicker response times and more streamlined operations with minimal human intervention.

Seamless Scalability and Adaptability:

Automated systems are both scalable and flexible, capable of handling increased inventory volumes and adapting to evolving business needs. By harnessing the power of automation, manufacturers can optimize their inventory management system, achieve operational excellence, and gain a competitive edge in the market.

Data-Driven Insights:

One of the major advantages of automation is the ability to collect, analyze, and derive actionable insights from data. This drives informed decision-making and optimizes stock levels based on real-time demand and sales trends.

Operational Cost savings and Waste Reduction:

Automation prevents over-purchasing or under-stocking, optimizing storage costs and reducing losses from expired or obsolete stock. This reduction in stockouts, overstock, and wastage significantly cuts carrying costs, eliminates waste, and improves cash flow.

Enhanced Customer Satisfaction and Loyalty:

Out-of-stock products can frustrate customers. Automation enables efficient management of inventory and production processes, enabling businesses to respond quickly to customer demands and deliver customized products. This leads to improved customer experiences, enhanced loyalty, and repeat business.

Increased Visibility and Transparency in Inventory Management:

Automation through inventory management technology provides real-time visibility into inventory levels, locations, and movements across multiple warehouses or sales channels. This facilitates proactive decision-making, improved demand planning, and better coordination across the supply chain.

Efficiency and Productivity:

Automation leads to faster and more consistent task completion. This efficiency increases productivity, freeing up staff for higher-value tasks and strategic planning.

Indeed, the rapid adoption of Inventory Management Automation (IMA) is intrinsically tied to remarkable technological advancements.

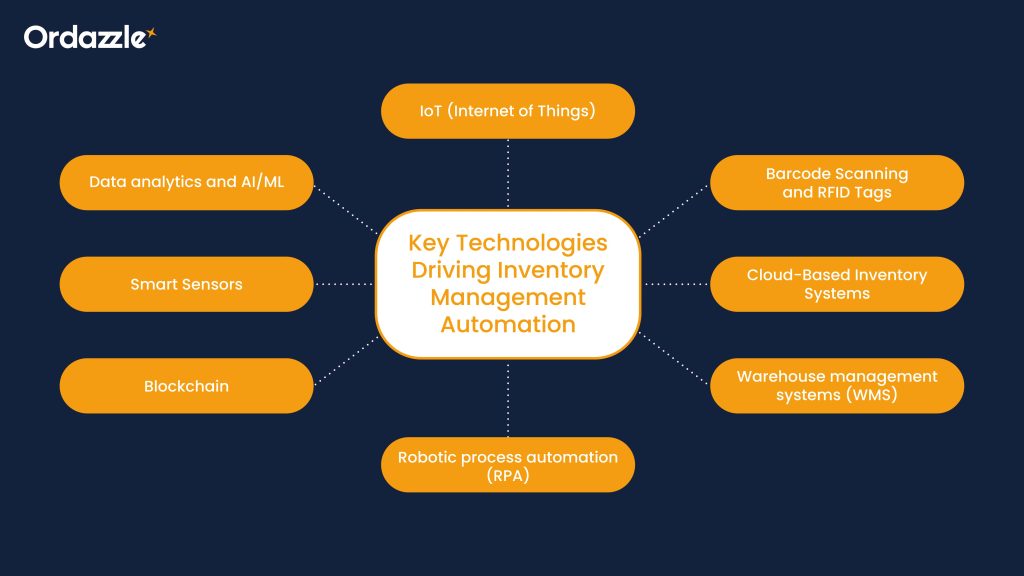

Key Technologies Driving Inventory Management Automation

IoT (Internet of Things):

IoT allows the connection of physical devices and sensors to the internet, enabling real-time inventory tracking and monitoring. These devices collect data on inventory levels, location, and condition, offering valuable insights for effective operations of the inventory management system. This real-time monitoring ensures that inventory levels are optimal, reducing the risks of stockouts or overstocking.

Barcode Scanning & RFID Tags:

Barcodes and RFID tags are fundamental technologies for automated product identification, tracking, and counting inventory items. Barcodes require direct line-of-sight scanning, while RFID tags can be read from a distance, even if they are not visible. This significantly speeds up the stock-taking process, reducing manual data entry errors.

Cloud-Based Inventory Systems:

Cloud solutions provide flexibility in accessing inventory data from anywhere, anytime. They also facilitate seamless integration with other business systems while ensuring that data is always backed up and protected.

Warehouse management systems (WMS):

Inventory Management technology and tools like WMS software automates and optimizes warehouse operations, including inventory receiving, put-away, picking, and shipping. These systems enhance inventory accuracy, streamline order fulfillment processes, and improve warehouse layout and space utilization.

Robotic process automation (RPA):

RPA utilizes software robots or bots to automate repetitive and rule-based tasks with high precision and speed. In inventory control, RPA automates data entry, reconciliation, report generation, and other administrative processes, reducing manual effort and enhancing accuracy.

Blockchain:

Blockchain technology establishes a transparent and immutable ledger for inventory transactions, ensuring traceability and reducing the risk of fraud.

Smart Sensors:

These sensors can detect environmental changes, such as temperature or humidity, that may affect inventory items, guaranteeing the maintenance of product quality.

Data analytics and AI/ML:

Advanced analytics techniques and Inventory Management technology like AI and ML can provide extensive datasets, including historical sales data, supplier information, and market trends. They generate precise demand forecasts, optimize inventory levels, and detect patterns for informed decision-making. Machine learning algorithms allow businesses to understand intricate sales data patterns, predict future trends, and adjust inventory levels accordingly.

These technologies collectively drive inventory management automation, offering businesses the tools they need to improve efficiency, accuracy, and adaptability. As technology advances, the potential for further enhancements and refinements in inventory management automation is expanding.

Future of Inventory Management Automation

The future of Inventory Management Automation (IMA) holds great promise. As technology advances, we can anticipate increasingly sophisticated and refined automation solutions. Consider the possibilities of drones for stock-taking, augmented reality for warehouse navigation, AI-driven bots directly communicating with suppliers in real-time, or predictive analytics capable of foreseeing global supply chain disruptions.

Going forward, technologies like AI and ML will increasingly be integrated into inventory management systems, enabling more intelligent and automated decision-making. By leveraging AI and ML, these systems will dynamically adjust the reorder points, optimize safety stock levels, and predict potential supply chain disruptions. Such e-commerce inventory management software also supports predictive maintenance of automated systems, ensuring seamless operations and minimizing downtime.

Conclusion

In an era where efficiency and data take center stage, Inventory Management Automation emerges as a cornerstone for modern businesses striving for growth, profitability, and sustainability. With the added promise of increased scalability and enhanced operational control, there is little reason not to embrace the power of automation.

As technology permeates every aspect of business, those who adopt and adapt will undoubtedly maintain a competitive edge.

However, the key lies in the implementation processes thoughtfully, with planning, continuous monitoring, and adaptability to ensure successful integration and mitigate potential challenges or risks.